Infrastructure

Main production machinery comprises a 1.5 & 0.75 Ton Belt Drop Hammers with an annual capacity of 1400 Metric Tons forging of carbon and alloy steel, non-ferrous, special metals viz. Titanium & Nickel Base alloys, Stainless steel etc, The supporting machinery consist of 200 Tons & 150 Tons trimming presses, oil fired furnaces for billet heating & heat treatment, bar shearing machine, Shot blasting machine etc.

BELT DROP HAMMER 1.5 T |

BELT DROP HAMMER 0.8 T |

TRIMMING PRESSES |

|

|

|

| . | ||

AUTOMATIC BANDSAW MACHINE |

AUTOMATIC CIRCULAR SAW MACHINE |

SHEARING MACHINE |

|

|

|

Die Design and Development

IMF's design & engineering capabilities are ably backed by a well equipped Die Shop, set up along modern lines with Milling Machine, Spark Erosion Machine (EDM), Radial Drilling machine, Lathes, etc. The design and development of the die holds the key to blemish-free forgings. At IMF, we design dies for all types of forgings. The design, of course, is related to the forging drawings. And the decision on the type of die to be used is based on the specific requirement of each case. The care that goes into the design of each die also goes into the selection of raw materials and the sequence of operation that follows.

VMC MACHINE |

MILLING MACHINE |

PLANO MILLER MACHINE |

LATHE MACHIN |

|

|

|

|

Forging and Heat Treatment Facilities

The billets for forging are heated in oil fired, closely controlling the temperature to reduce the scale formation and overheating so that the metallurgical properties are ensured in the final product. In addition, in-process inspection is carried out at all stages viz. at forging stage and cent percent inspection for visual defects after forging. The accepted forgings are duly heat-treated. By providing heat treatment services in-house, IMF is able to maintain greater control over heat-treating process. The facility comprises oil fired batch furnace, etc. to carry out annealing, normalizing etc. & other operations as specified by our customer. Close temperature control and process monitoring with the help of temperature controllers, ensures uniform properties duly supported by evaluation of metallurgical properties through representative test pieces

INHOUSE CONTINUOUS NORMALISING FURNACE |

INHOUSE CONTINUOUS NORMALISING FURNACE |

OUTSOURCED AT AKAS HEAT TREATERS |

OUTSOURCED AT AKAS HEAT TREATERS |

|

|

|

|

| . | |||

OUTSOURCED AT AKAS HEAT TREATERS |

200 KW INDUCTION BILLET HEATING |

400 KW INDUCTION BILLET HEATING |

|

|

|

|

Testing and Inspection Facilities

Surface conditioning is done by shot blasting/grinding and final inspection is carried out once again to ensure quality requirements. Stage-wise inspection for non-conformities is taken care of by timely corrective and preventive action. IMF has set up a system of total quality control (TQC), consisting of an array of state-of-the-art specialty equipment’s, where your products go through a series of rigorous tests, Jominy testing, wet analysis, carbon-Sulphur determination, metallography and non-destructive tests using Ultrasonic flaw detection, Magnaflux crack detection, that ensures quality. Setting and control of quality standards at all stages right from the receipt of raw material to the finished product through quality plan makes us deliver superior quality forgings with close dimensional tolerances and metallurgical properties.

SHOT BLASTING MACHINE |

MPI TESTING MACHINE |

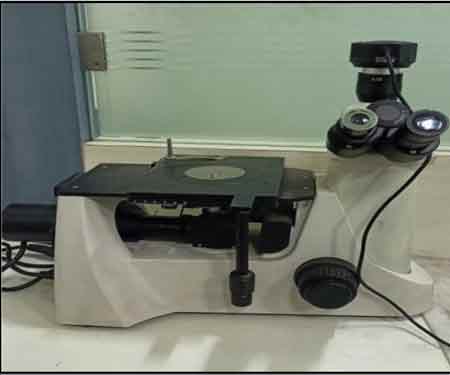

Microscope |

HARDNESS TESTING MACHINES |

|

|

|

|

| . | |||

HARDNESS TESTING MACHINES |

JOMINY END QUENCH TESTING |

MUFFLE FURNACE |

|

|

|

|

List Of Machinery:

FORGE SHOP

SR.NO |

MAJOR MACHINERY |

QTY |

Make |

Type |

Capacity |

1 |

Belt Drop Hammer –1.5 Ton |

1 |

Rajan Hammers |

Friction Belt Drop |

Forgings up to 7.5 Kg. |

2 |

Belt Drop Hammer – 0.8 Ton |

1 |

NSE- Massey |

Friction Belt Drop |

Forgings up to 3 Kg. |

3 |

Trimming Power Press 200 Tons |

1 |

Ravi Presses |

Pillar |

200 Tons |

4 |

Trimming Power Press 150 Tons |

1 |

Aman power press |

Pillar |

150 Tons |

5 |

200 KW Billet Heater |

1 |

Megatharm |

Induction |

40 & 56 Dia |

6 |

400 KW Billet Heater |

1 |

Megatharm |

Induction |

65 RCS & 100 Dia |

7 |

Air Compressor |

4 |

Annest Iwata |

Reciprocating |

Max. Pressure 10Kg/cm2-45CFM |

8 |

Welding Machine |

1 |

Advani |

Three Phase |

400 AMP |

MACHINE SHOP

SN |

Machines | Qty |

Make |

Type |

Capacity |

1 |

CNC Turning Centre | 3 |

ACE Micromatic |

Fanuc System 0i- MF |

200 mm Dia |

2 |

CNC Turning Centre | 1 |

Global |

Fanuc System 0i- MF |

200 mm Dia |

3 |

CNC Turning Centre | 2 |

Mori-Seiki |

Fanuc System 0i- MF |

200 mm Dia |

INSPECTION & TESTING EQUIPMENTS

SN |

Machinery & Testing Equipment | Qty |

Make |

Type |

Capacity |

1 |

Height Gauge | 1 |

Mitutoyo |

Digital |

300 mm |

2 |

Vernier | 4 |

Mitutoyo |

Digital |

200 mm |

3 |

Vernier | 2 |

Mitutoyo |

Digital |

300 mm |

4 |

Micrometer | 2 |

Mitutoyo |

Digital |

50 mm |

5 |

Micrometer | 1 |

Mitutoyo |

Digital |

75 mm |

6 |

Surface Plates | 1 |

Luthra |

630 mm X 630 mm |

|

7 |

Micrometer | 1 |

Mitutoyo |

Analog |

25 mm |

8 |

Micrometer | 1 |

Mitutoyo |

Digital |

25 mm |

9 |

Run out Stand | 1 |

Crystal |

||

10 |

Dial Gauges | 2 |

Mitutoyo |

Analog |

21 Micron |

11 |

Dial Gauges | 2 |

Mitutoyo |

Analog |

10 Micron |

12 |

Dial Gauges | 2 |

Mitutoyo |

DIE SHOP

SN |

Machinery & Testing Equipment | Qty |

Make |

Type |

Capacity |

1 |

VMC |

1 |

ACE Micromatic |

Fanuc System 0i- MF |

Equipped with CAD/CAM Software |

2 |

Vertical Milling Machine |

1 |

HMT |

FN 3V |

Max 350 mm Height |

3 |

Plano Milling Machine |

1 |

Huddersfield Ltd. |

6’-0”*2’-6” size |

|

4 |

Lathe 12’’ Center, Bed 6 feet |

1 |

Ess Pee Ind. |

With Semi Norton Gear |

200 Kgs |

5 |

Lathe 20” Centre, Bed 12 fee |

1 |

Ess Pee Ind. |

With Semi Norton Gear |

600 Kgs |

6 |

Lathe 12” Centre, Bed 5.5 feet |

1 |

Sagar |

With Semi Norton Gear |

200 Kgs |

7 |

Pneumatic Air Grinder |

4 |

C-P Tools |

3050 & 3051 |

|

8 |

Radial Drilling Machine |

1 |

Energy |

Radial, Fully Geared |

32mm |

9 |

EDM (Spark Erosion Machine) |

1 |

MMT |

Hydraulic Ram |

60 Amps. With 800x500x500 |

10 |

D.C. Welding Rectifier |

1 |

Esab |

400 AMP |

|

11 |

Pedestal Grinder |

1 |

Grind Tool |

Wheel Ø 200 mm |

|

12 |

Electrical Hand Grinder |

1 |

Dewalt |

Angle Grinder |

Wheel Ø100 & 175mm |

CUTTING

SN |

Machinery & Testing Equipment | Qty |

Make |

Type |

Capacity |

1 |

BilletShearing Machine | 1 |

Shree Engineering Works |

Mechanical |

75 RCS mm Max |

2 |

Bandsaw-6’’ | 2 |

Laxmi Engg works |

Semi automatic |

160 mm Max |

3 |

Fully Automatic Band Saw Machine | 2 |

Aditya |

Automatic |

250 Ø |

4 |

HIGH Speed Circular Saw CSNC-80XL | 1 |

ITL Industries |

CSNC Machine |

80 Ø |

LABORATORY

SN |

Machinery & Testing Equipment | Qty |

Make |

Type |

Capacity |

1 |

Rockwell Hardness Machine | 1 |

FTM Make |

Model - OTRS |

|

2 |

Metal Spectroscope | 1 |

SICO Feedback |

Model 1500 |

|

3 |

Polishing Machine | 1 |

Vardhan |

Single Spindle |

|

4 |

Carbon & Sulphur Determinator | 1 |

Abort Ind. |

Combustion |

|

5 |

Muffle Furnace | 1 |

Shital Scientific |

0 to 1000oC |

|

6 |

Laboratory Balance | 1 |

Tapson |

Single pan |

0.1 mg to 100 gm |

7 |

Hot Plate | 1 |

Steel Anal. |

3 KW |

|

8 |

Distilled Water Plant | 1 |

Steel Anal. |

2 KW |

2 Lit/Hr. |

9 |

Jominy Hardnability Test Equip. | 1 |

Indigenous |

||

10 |

Microscope | 1 |

Vardhan |

Inverted Metallurgical Microscope |

500X (Magnification) |

11 |

Microscope | 1 |

Daksh Quality Systems |

Inverted Metallurgical Microscope |

1000X (Magnification) |

HEAT TREATMENT

SN |

Machinery & Testing Equipment | Qty |

Make |

Type |

Capacity |

1 |

Continues Normalizing Furnace | 1 |

Ashwini Engg |

Automatic |

7 Tons per day |

2 |

Hardness Testing Machine | 1 |

FTM |

TKB-3000 |

3000 Kg / 10 mm |

3 |

Optical Hardness Testing Machine | 1 |

FTM |

TKB-3000 |

3000 Kg / 10 mm |

4 |

Pedestal Grinder | 2 |

Grind Tool |

2HP |

Wheel Dia 250 MM |

1 |

Optical Hardness Testing Machine | 1 |

FTM |

TKB-3000 |

3000 Kg / 10 mm |

GRINDING & FINISHING

SN |

Machinery & Testing Equipment | Qty |

Make |

Type |

Capacity |

1 |

Shot Blasting Machine | 1 |

Peen-Blast |

Rotoblast |

400 Kg / Charge |

2 |

Shot Blasting Machine | 1 |

Indian Harvester |

Automatic Loader |

150 Kg / Charge |

3 |

Pedestal Grinder | 2 |

Grind Tool |

Wheel Ø 300 mm |

|

2 |

Belt Grinder | 2 |

Indigenous |

3 HP |

INSPECTION & QUALITY CONTROL

SN |

Machinery & Testing Equipment | Qty |

Make |

Type |

Capacity |

1 |

Magnaflux M/c with Demagnetiser | 1 |

Mayuresh |

EMCO 457 55P |

2500A-15KAT |

2 |

All Measuring instrument Includes surface plate, height gauges, Vernier calipers, radius gauges, V blocks, pistol callipers etc | Mitutoyo |